Improve uptime with AI and ML and reduce cost

Each valuable machine has multiple linked costs, and unexpected failure cost contributes significantly to the total cost of ownership of any equipment. Therefore, production units can save money by being able to predict and avoid equipment failure. In machine-intensive industries, improving maintenance approach can result in huge savings. IoT-based predictive maintenance leverages historical data from multiple sources including IoT devices and sensors to make accurate predictions about machine health, utilisation, and the possibility of failure, enabling you to take action based on this information. IoT-based predictive maintenance allows you to systematically schedule the optimal maintenance and inspection routine to avoid unplanned downtime and unnecessary effort. Avoidable costs can be reduced significantly and you can also reduce the amount of time the machinery or equipment is down for maintenance.

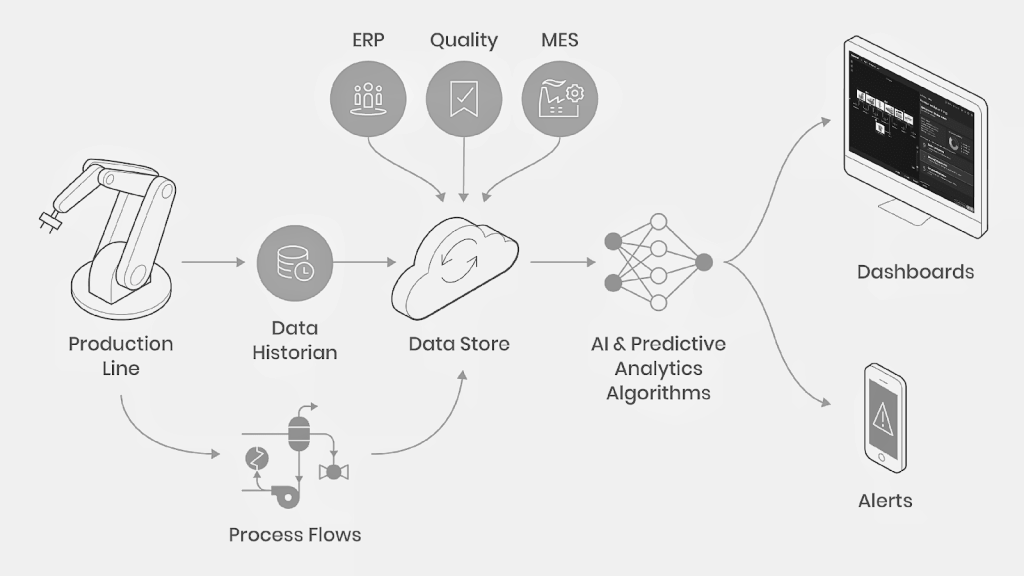

Our backend algorithms either deployed on premise or on cloud does all the heavy lifting in both real time data streams and analytical data sets. This enables smart maintenance and planned downtime.